Reengineering Navy Food Service

Moving from Innovation to Implementation

By Cmdr. Steven Romano, SC, USN

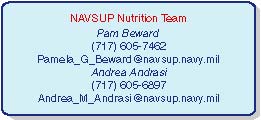

Over the past years, the fleet and Naval Supply Systems Command have conceived and executed innovative concepts and ideas in food service. Our challenge has been to move from the traditional general mess environment to adopting the latest proven industry standards and innovative solutions. Ships and shore activities making appropriate selection and adoption of these tools and concepts have experienced improvements in Sailors’ and Marines’ quality of life (QOL) and reduction in workload. All activities are encouraged to evaluate food service initiatives and incorporate ideas, as appropriate, into their operations. The NAVSUP Food Services Division is actively assisting fleet customers to maximize the use of these initiatives to optimize their work processes. Key NAVSUP points of contact are provided in this article.

Today is an exciting time to work in the food service business as change can bring about significant opportunities for success and improved operational readiness. Taking full advantage of these new tools coupled with leadership, a commitment to excellence and essential training will move Navy food service into the 21st century.

Deckplate innovation

Self-Service

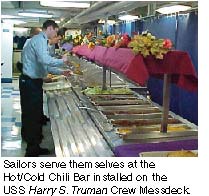

Serving Lines. The use of self-service lines reduces food

service attendant (FSA) workload. While, initially targeted for CVNs and

amphibious platforms, small ships have also adopted this approach as

well. In the past year, USS Harry S. Truman (CVN 75), USS John

S. McCain (DDG 56), and USS Tarawa (LHA 1) have tested and

adopted self-service lines. Chief Warrant Officer 4 Leon Cole, SC, USN,

Food Service Officer, USS Harry S. Truman (CVN 75) pioneered

development and use of such lines on his carrier. He converted his

traditional serving line and built a hot and cold chili bar on his aft

crew mess decks. In conjunction with this effort, Cole adopted

continuous feeding allowing crewmembers an opportunity

Self-Service

Serving Lines. The use of self-service lines reduces food

service attendant (FSA) workload. While, initially targeted for CVNs and

amphibious platforms, small ships have also adopted this approach as

well. In the past year, USS Harry S. Truman (CVN 75), USS John

S. McCain (DDG 56), and USS Tarawa (LHA 1) have tested and

adopted self-service lines. Chief Warrant Officer 4 Leon Cole, SC, USN,

Food Service Officer, USS Harry S. Truman (CVN 75) pioneered

development and use of such lines on his carrier. He converted his

traditional serving line and built a hot and cold chili bar on his aft

crew mess decks. In conjunction with this effort, Cole adopted

continuous feeding allowing crewmembers an opportunity

to eat when they

are hungry. This concept actually reduced waiting time in line and

improved Sailor QOL. According to Cole, "Sailors were very

enthusiastic about the positive changes ‘Team Truman’ made in

his food service operation."

to eat when they

are hungry. This concept actually reduced waiting time in line and

improved Sailor QOL. According to Cole, "Sailors were very

enthusiastic about the positive changes ‘Team Truman’ made in

his food service operation."

On

board USS John S. McCain (DDG 56), Lt. Thomas James

implemented a self-serve line. With small modifications to his line and

with the dome covers, the crew were able to serve themselves. James

reported, "…the line was a hit with the crew and we have received

nothing but positive accolades thus far." McCain was able to

reduce its total FSA requirement from 17 to 14 as the result of the new

line. NAVSUP is working with Naval Ships System Engineering Station (NAVSSES)

to complete self-serve line ship checks and drawings that would support

installation on CVNs and amphibious

ships. Self-service line

installation is not limited to those ships, and interested personnel

should contact type commander staff, port engineers, or the NAVSUP

equipment team to facilitate the planning and installation process.

NAVSUP is funded to support self-serve line conversions through fiscal

year ’03.

ships. Self-service line

installation is not limited to those ships, and interested personnel

should contact type commander staff, port engineers, or the NAVSUP

equipment team to facilitate the planning and installation process.

NAVSUP is funded to support self-serve line conversions through fiscal

year ’03.

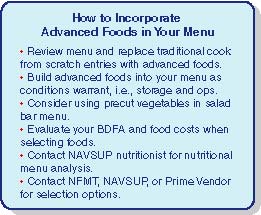

Advanced Food Technology augments traditional cook from scratch methods with prepared or precooked bulk items to achieve workload savings. USS Rainier (AOE 7) and USS McFaul (DDG 74) prototyped the concept serving advanced foods such as precooked bacon, precooked beef patties, precooked deep fried chicken, precooked vegetable and beef lasagna, and frozen dough.

According

to Ens. Tracey Tobias, food service officer for the USS Kearsarge

(LHD

3), "We surveyed the crew from our food show and the results are

in! Chicken Battered Fries, Grilled Chicken, Fiery Hot Chicken Fries,

Alfredo Sauce, Spicy Fries, and Turkey topped the list as the most

popular items."

According

to Ens. Tracey Tobias, food service officer for the USS Kearsarge

(LHD

3), "We surveyed the crew from our food show and the results are

in! Chicken Battered Fries, Grilled Chicken, Fiery Hot Chicken Fries,

Alfredo Sauce, Spicy Fries, and Turkey topped the list as the most

popular items."

As the single-ship prototype for SECNAV food service initiatives, USS Tarawa (LHA 1) demonstrated that using pre-prepared foods in port could reduce workload by 10 percent. From USS Rainier (AOE 7) prototype, it was concluded about 40 percent of food served should be advanced foods. Funding has been approved for ships to purchase advanced foods up to this percentage. A food flash describing food allowance for advanced foods was released in November.

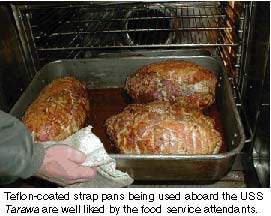

Coated

Cooking Pans. The use of protective coating

pans reduces cleaning time. NAVSUP is reviewing final results of USS Tarawa

(LHA 1) prototype and fleetwide purchase is scheduled for November

2000. We have already received feedback that pre-existing handling

methods, such as using abrasive utensils and stacking of these new pans

will cause minor surface damage. According to MSCS Donellan on

USS Supply, "The pans have incurred some minor scratches due

to metal spatulas used for removal of products, however it has not

decreased any value of time in both cooking or cleaning. He reports,

"The food service attendants like the pans and want to get

more." The fleet will receive their allowance of pans in fiscal

year ’01 as well as appropriate standard operating procedures for

their use. Pans have an estimated shelf life of 24 months, so

replacement pans will be provided every two years until fiscal year ’07.

use of protective coating

pans reduces cleaning time. NAVSUP is reviewing final results of USS Tarawa

(LHA 1) prototype and fleetwide purchase is scheduled for November

2000. We have already received feedback that pre-existing handling

methods, such as using abrasive utensils and stacking of these new pans

will cause minor surface damage. According to MSCS Donellan on

USS Supply, "The pans have incurred some minor scratches due

to metal spatulas used for removal of products, however it has not

decreased any value of time in both cooking or cleaning. He reports,

"The food service attendants like the pans and want to get

more." The fleet will receive their allowance of pans in fiscal

year ’01 as well as appropriate standard operating procedures for

their use. Pans have an estimated shelf life of 24 months, so

replacement pans will be provided every two years until fiscal year ’07.

|

|

|

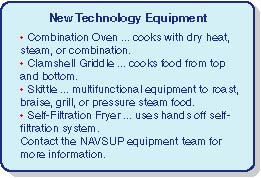

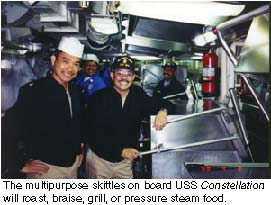

New Technology Galley Equipment incorporates latest technology in commercial sector and reduces total food service equipment ownership costs. Several ships are using new technology equipment including USS Rentz (FFG 46), USS John C. Stennis (CVN 74), USS Constellation (CV 64), USS Supply (AOE 6), USS Rainier (AOE 7), USS Arctic (AOE 8), USS Vicksburg (CG 69), USS Decatur (DDG 73), USS Carl Vinson (CVN 70) and USS Kitty Hawk (CV 63).

The skittle is one example of new technology equipment enjoying success in the fleet today. The skittle’s versatility and its ability to cook foods in a wide range of applications from boiling and steaming through roasting and sautéing has resulted in numerous positive fleet feedback. Whether griddling pancakes, pork chops, or hamburgers or boiling water for pasta noodles or stir frying, the skittle is worth its weight in gold. NAVSUP is working with NAVSEA Program Executive Offices to develop new technology equipment POM issue papers for submission in PR03 process.

Contractor

Load Out of Stores Replaces Sailor working parties in homeport

with contractors. The primary benefit of this initiative was increased

time available throughout each department to perform divisional work by

eliminating a menial task that interfered with ship’s routine. The

plan is for subsistence, including dry, frozen, fresh fruits,

vegetables, and dairy, products to be delivered on the pier and loaded

by contract workers into food service storerooms on board. Based on USS Tarawa

prototype business case analysis, the contractor load out of stores

initiative eliminated menial work, reallocated workload, and improved

morale of the crew. The contractor also demonstrated the same or better

efficiency loading stores by reducing the amount of time required to

perform each function. Funding for this initiative has been approved for

FY ’02. NAVSUP is working with Defense Supply Center,

Philadelphia and Fitting Out and Supply Support Assistance Center to implement

contractor load out of stores at all Navy homeports, including overseas

locations such as Agana, Gaeta, La Maddalena, Sasebo, and Yokosuka in FY

’02.

Contractor

Load Out of Stores Replaces Sailor working parties in homeport

with contractors. The primary benefit of this initiative was increased

time available throughout each department to perform divisional work by

eliminating a menial task that interfered with ship’s routine. The

plan is for subsistence, including dry, frozen, fresh fruits,

vegetables, and dairy, products to be delivered on the pier and loaded

by contract workers into food service storerooms on board. Based on USS Tarawa

prototype business case analysis, the contractor load out of stores

initiative eliminated menial work, reallocated workload, and improved

morale of the crew. The contractor also demonstrated the same or better

efficiency loading stores by reducing the amount of time required to

perform each function. Funding for this initiative has been approved for

FY ’02. NAVSUP is working with Defense Supply Center,

Philadelphia and Fitting Out and Supply Support Assistance Center to implement

contractor load out of stores at all Navy homeports, including overseas

locations such as Agana, Gaeta, La Maddalena, Sasebo, and Yokosuka in FY

’02.

On

the horizon. NAVSUP is continually evaluating new initiatives to

improve the quality of food service by streamlining business practices,

improving training, and seeking solutions to equipment material

condition. First target of opportunity this fiscal year is to merge four

food service publications into one. Plans are underway to combine NAVSUP

P-486, 421, 520, and 580. Distribution is scheduled in 2001. In

addition, NAVSUP and CINCPACFLT are reviewing Mess Management Specialist

(MS) A school to evaluate implementing American Culinary Federation (ACF)

training log (commercial version of MS PQS) into the training pipeline.

The training goal would allow first term MSs to work toward completion

of Certified Culinarian (CC) qualifications. Currently, NAVSUP and

NAVSEA are partnering to develop funding packages to replace traditional

equipment with new technology equipment.

On

the horizon. NAVSUP is continually evaluating new initiatives to

improve the quality of food service by streamlining business practices,

improving training, and seeking solutions to equipment material

condition. First target of opportunity this fiscal year is to merge four

food service publications into one. Plans are underway to combine NAVSUP

P-486, 421, 520, and 580. Distribution is scheduled in 2001. In

addition, NAVSUP and CINCPACFLT are reviewing Mess Management Specialist

(MS) A school to evaluate implementing American Culinary Federation (ACF)

training log (commercial version of MS PQS) into the training pipeline.

The training goal would allow first term MSs to work toward completion

of Certified Culinarian (CC) qualifications. Currently, NAVSUP and

NAVSEA are partnering to develop funding packages to replace traditional

equipment with new technology equipment.

Summary

Fleetwide

use of these concepts and tools is increasing. As a result, ships

are seeing reduced workload and improvements in quality of life. While

these initiatives have made improvements in food service, there is more

work to be done. As noted above, i improving equipment material condition

and food production training is needed and we are working these

challenges. As the fleet uses more of these products and concepts,

additional lessons will be learned and shared with the fleet. Success

will not be achieved overnight, but over time these changes will help

advance Navy food service into the 21st century.

improving equipment material condition

and food production training is needed and we are working these

challenges. As the fleet uses more of these products and concepts,

additional lessons will be learned and shared with the fleet. Success

will not be achieved overnight, but over time these changes will help

advance Navy food service into the 21st century.

Author's note: Cmdr. Karen Al-Koshnaw, Bill Lingle, and Jane McMullen contributed to this article.

CDR Steven Romano is the Director of Navy Food Service, providing policy and guidance to over 400 afloat and ashore general messes. His previous afloat tours include Supply Officer, USS Belleau Wood (LHA 3), USS Princeton (CG 59), and USS John A. Moore (FFG 19) and Sales/Disbursing Officer, USS Coronado (AGF 11). Shore tours include Defense Logistics Agency Headquarters, Fort Belvoir, Va.; Navy Supply Corps School, Athens, Ga.; Commander, Naval Surface Force, U.S. Pacific Fleet; and Naval Communications Unit, Washington, D.C. He has a master of science degree in logistics, National University, and bachelor of arts degree in government, College of William and Mary.

February 2001

| Bulletin Board | Keyword Search |

| Bookstore | Links |

| About Us | Recent Additions |