Food Processing Industry Advances

America's current food-processing industry can be traced back to a tasking by Napoleon that led his quartermaster to engage the services of Nicolas Appert to produce stable rations for his troops to carry into battle.

The

canning industry that originated in 1809 has evolved

during two centuries into a mature industry that still

relies heavily on thermal processing to feed a growing

population.

The

canning industry that originated in 1809 has evolved

during two centuries into a mature industry that still

relies heavily on thermal processing to feed a growing

population.

The Army used thermal processing to develop the C Ration, which evolved into the Meal, Combat Individual, that served U.S. troops from World War II through the Vietnam era. These rations relied on cylindrical metal cans.

In the late 1970s, the Army replaced metal cans with the more flexible and versatile polymeric retort pouch for improved thermally- processed products.

The retort pouch was developed by the Natick Soldier Center, part of the U.S. Army Soldier Systems Center (Natick), in cooperation with industry and academia, and it is the central feature of the Meal, Ready-to-Eat (MRE). The 21st version of this ration, which will be procured in 2001, will have 24 different meals, each with a different entree in a retort pouch.

To increase the mobility of individual soldiers, lightweight, calorically-dense or dehydrated rations are required. The freeze-dehydration process pioneered by the Natick Soldier Center is capable of producing high-quality meals with long shelf life.

This process produced the Long Range Patrol ration first used during the Vietnam conflict, and it is now used by industry for backpacker meals and survival rations, as well as for a variety of food ingredients.

Current efforts are focused on cost-effective dehydration processes, such as osmotic dehydration and the development of ready-to-eat, partially dehydrated intermediate moisture items.

The military has continually exploited a variety of mechanical, chemical and electromagnetic energy sources and technologies for purposes of offense, defense or communication.

Numerous electromagnetic energy sources-initially developed for other purposes-can now be used for food and other materials processing.

A variety of sources of energy across the electromagnetic spectrum may now be focused on food processing and other materials transformation mation processes. They are a dividend from generations of research aimed at much larger targets than the microorganisms that present threats to stability and safety of food materials.

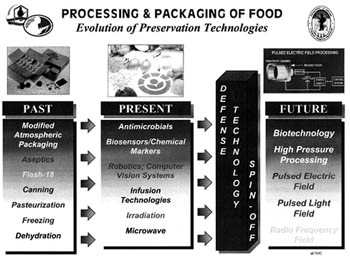

Figure 1, which is adapted from a recent book on aseptic processing and packaging of foods (see footnote), captures a timeline for defense technology spin-offs to the food-processing industry. Currently, a considerable variety of thermal and nonthermal processes are being assessed to improve combat ration quality and variety. Among the thermal processes are high-temperature, short-time processes, including ohmic, microwave, radio frequency and induction heating.

The Natick Soldier Center and its precursor, the Quartermaster Food and Container Institute in Chicago, pioneered early research on nonthermal processes. The research explored food preservation potential of ionizing radiation (from both gamma and electron beam sources). The Natick program was transferred to the USDA in 1980. However, data from the Natick project have been important in getting the approval of low-dose irradiation to improve the safety of fresh meat products and to extend the shelf life of fresh produce. Sterilized irradiated meat items prepared for NASA under Natick Soldier Center guidance are currently used in the Space Shuttle program.

Other pacing technologies envisioned for 21st century combat rations are two nonthermal processes, pulsed electric field (PEF) and high pressure (HP) preservation.

The latter is also referred to as hyperbaric pressure preservation. PEF processing is applied to liquids or pumpable products using a flow-through treatment chamber as depicted in Figure 1.

HP preservation can be applied to either liquid or solid foods in flexible containers. The improved food preservation technologies are being used to:

- Minimize processed-induced loss of

color, flavor, texture, and nutrition.

- Retain the highest possible quality in stressful

storage environments.

- Provide shelf-stable foods with fresh food attributes.

- Optimize ration variety, acceptance and consumption.

- Reduce the logistics burden and cost vs.

conventionally-processed foods.

- Enhance the overall quality of life of the service

member.

Because

nonthermal processing is relatively new compared to

conventional processing, two key issues are particularly

critical for PEF and HP technologies. The first major

issue is safety and process assurance; the second is

sensory quality and consumer acceptance over the intended

shelf life.

Because

nonthermal processing is relatively new compared to

conventional processing, two key issues are particularly

critical for PEF and HP technologies. The first major

issue is safety and process assurance; the second is

sensory quality and consumer acceptance over the intended

shelf life.

For military use that shelf life must be at least 3 years at 80 degrees Fahrenheit and 6 months at 100 degrees Fahrenheit. Several products made shelf-stable by nonthermal technologies were selected for microbiological and sensory assessment from the output of feasibility study contracts conducted 1992-1995. The contracts are as follows:

- Pulsed Electric Field (PEF)-FoodCo (now

PurePulse Technologies), San Diego, Calif. Demonstration

products were spaghetti sauce with meat, banana yogurt

drink, milk and orange juice, a refrigerated product.

- Hyperbaric Pressure Preservation-Oregon State

University and University of Delaware. Demonstration

products were Spanish rice, spaghetti with meat sauce,

fruit salad and yogurt with peaches.

After the products were shown to be microbiologically safe, sensory screenings were conducted against available, equivalent commercial products, military products or both using standard descriptive and/or consumer acceptance methods.

|

Pulsed Electric Field processing is a pasteurization process for fresh or fresh-like foods, such as salsa. |

As an example, batch-processed demonstration HP products submitted by Oregon State University were spaghetti with meat sauce and Spanish rice packed in 8-ounce polymeric bowls with aluminum tear-off closures treated in-package at 75,000 psi for 20 minutes.

Despite the infancy of HPP processing, consumer panelists appearance, flavor and texture ratings of the spaghetti and rice items met or exceeded benchmark products both initially and after one year of storage at 80 F. A follow-on technology demonstration effort on HP processing was conducted under the leadership of Oregon State University.

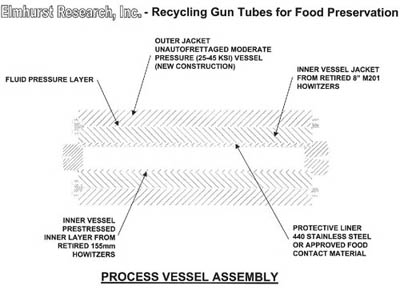

One thrust was to optimize throughput and efficiency of a batch high-pressure processing system. Elmhurst Research, Inc., which turned to cannon technology for inspiration, developed a novel design for a batch processing system.

This effort has become a true "guns-to-plowshares" event in that a prototype system is now under development that uses recycled 6-inch cannon tubes as pressure vessels (Figure 2).

The Army's assessment of these novel technologies indicates that they do have considerable technology transfer potential to the food industry in view of the following:

- Consumer demand for minimally-processed

foods with maximum nutrient retention.

- Continuing consumer demand for high quality and

convenience along with assurance of safety.

- International competition in the industry.

As examples, ohmic (thermal) products are now commercial in Europe and Asia, and HP products are commercial in Japan. As noted earlier, the military is a potential beneficiary of technological advances in food processing to support integrated and focused logistics for battlefield operations and peacekeeping missions.

Finally, the role of the DoD Combat Ration Program is seen as serving as a catalyst for the food processing industry by securing considerable leveraging of resources through academic, industrial, government, and trade, technology or industry association partners in the United States and abroad. In this regard, the DoD has co-sponsored workshops of nonthermal researchers from industry, academia and government to jointly address the key technical barriers to commercialization of PEF and HP processing.

These workshops have led to the formation of a new Division of Nonthermal Processing for the Institute of Food Technologists.

The application of pulsed power technology to food preservation is being facilitated by a Fiscal Year 1999 Dual Use Science and Technology project.

The project for a Pulsed Electric Field Food Processing Consortium will be led by Ohio State University and industrial partners, including PurePulse, Inc.; TetraPak; Kraft; Nestles; and General Mills.

Industrial adoption of advanced food processing technologies will enhance the sustainment of our warfighters and will contribute to a more flexible and responsive logistics system.

Reference

J.R.D. David, R.H. Graves and V.R..Carlson, Aseptic

Processing and Packaging of Food, CRC Press, Boca Raton,

Fla. (1996) p.198.

A Natick Warrior story from the November/December 1999 issue.

January 2000

| Bulletin Board | Keyword Search |

| Bookstore | Links |

| About Us | Recent Additions |

![]()