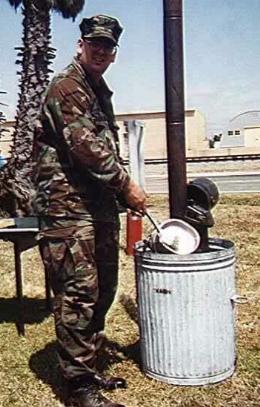

Seabee Field Dishwashing Battery

Reprinted from Chapter 5 of Logistics Support for the Naval Construction Force: Field Messing, Seabee Logistics Training Guide Series, Module No. 7

[Set up and location] [Garbage

cans] [Washing procedures]

[Cleaning mess kits] [Chemical

sanitizing]

The field dishwashing battery must be located at least 50 feet from any food preparation, serving, or eating area. This is needed so carbon monoxide, smoke, and soot do not blow back into food service area. See Chapter 4 for a complete description of battery location. It is best to locate mess kit batteries close to the exits of the mess tent and the pot and pan washing battery in close proximity to the galley and serving tents. Make sure that sufficient drainage is provided to prevent standing water.

The five 32-gallon corrugated garbage cans are set up in a straight line as follows:

-

First can -- Scrap can: used to collect garbage; if available, line with plastic trash can liners.

-

Second Can -- Pre-wash: contains hot soapy water and a log-handled brush for the first wash.

-

Third can -- Wash: contains hot soapy water and a long-handles brush for the second wash.

-

Fourth Can -- First rinse: contains clear boiling water for the first sanitizing rinse.

-

Fifth can -- Final rinse: contains clear boiling water for the second, or final, sanitizing rinse.

Note that the Army uses a four-can set up, including one waste can and three cans with immersion heaters, mounted as follows: wash can, rinse can, and final rinse can. Do not use this method of immersion heater set up without first consulting the Medical Department. The Navy and Marines use two wash cans to insure that individual mess kits are properly cleaned before rinsing. If immersion heaters are in short supply, NAVMED P-5010-9, Article 9-20 authorizes the use of three immersion heaters for pot and pan washing. In this case, the first can is the wash can; the second can is the first rinse; and the third can is the sanitizing rinse.

Each 32-gallon garbage can must be permanently marked to identify its use. Stencil (or otherwise label) the cans as follows: garbage, pre-wash, wash, first rinse, and final rinse. Once marked, these cans must never be used for any other purpose.

Washing and sanitizing procedures

The mess deck master-at-arms (MDMAA) and mess management specialists (MS) must be ready to demonstrate to Seabees the proper procedure for washing and sanitizing their individual mess kits and eating utensils. During the first few meals in the field, be prepared to hold quick OJT sessions to train Seabees how to use the immersion heater battery. The procedure for washing and sanitizing mess kits and eating utensils is found in the table. This process is done by each Seabee after he or she is done eating. Food service attendants (FSA) assigned to pot and pan washing follow similar steps.

|

Chlorine-Iodine type -- Disinfectant, food service (NSN 6840-00-810-6396), issued in a 4.77 ounce pouch, was developed for low-temperature disinfection or sanitation in lieu of the hot water rinse. It is intended for use in the field where the rinsing water cannot be kept at the proper temperatures. When food service disinfectant is dissolved in water (between 75oF and 110oF), it releases both iodine and chlorine gas, which disinfects the utensils. This happens when the iodine and chlorine contact the utensil and the water is agitated. If the compound is dissolved in warm water (above 130oF), the halogen gases are released too rapidly and the disinfecting action is soon lost.

Make a chlorine-iodine solution for rinsing the washed equipment by dissolving the contents of one package of food service disinfectant in 20 to 25 gallons of warm water.(75oF and 110oF). If the water is cold, mix the contents of the package with a small amount of water in a container (such as a canteen cup), and pour the mixture into the rinse water. Stir thoroughly to dissolve. If using a different product, follow the manufacture’s instructions.

Make a fresh solution for every 80 Seabees. Never reuse a solution. Follow the procedures found in this section for washing equipment or individual mess gear. Disinfect utensils by swishing them in the chlorine-iodine water for at least one minute. This procedure can be used for immersion heater washing as well as with the Sanitation Center deep-sink.

Chlorine type -- NAVMED P-5010-1, Table 1-1, "Methods to Reduce Chlorine Sanitizing Rinse Time to 10 Seconds," contains instructions for using chlorine-based disinfectants. Follow the manufacture’s instructions when using these products. Instructions on the bottle will clearly state the amount of product to use per gallon, recommended rinse water temperatures and safety precautions.

August 1999

| Bulletin Board | Keyword Search |

| Bookstore | Links |

| About Us | Recent Additions |